Table of contents

- In brief

- Quick Installation

- Long-lasting autonomy

- Robust Communication

- Simplified Configuration

- Smart Detection

- Integrated exploitation

- A solution designed for the real

- A quick setup, no wiring, no tools

- Simple and guided setup

- An initial learning phase for the predictive maintenance algorithm

- Actionable and connected data

- Need to test? Let's start with a POC

In brief

Quick Installation

Wireless sensor, no wiring, installation in 5 min

Long-lasting autonomy

Up to 2 years with standard battery

Robust Communication

LoRaWAN transmission up to 13 km in free field

Simplified Configuration

Intuitive USB interface, no coding required

Smart Detection

Machine learning from 200 datasets

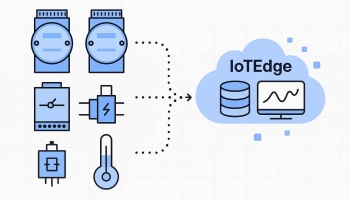

Integrated exploitation

Visualization on SCADA, IoT platform, or business tool

A solution designed for the real

Our predictive maintenance solution has been designed to meet the operational constraints of industrial environments. It installs easily, without production downtime, without wiring, and adapts to both a pumping station pump and a compressor in a clean room.

Concrete example: The sensor can be installed on a pump in a lift station or a compressor in a clean room without stopping production.

A quick setup, no wiring, no tools

The WISE-2410 sensor is delivered ready to use. It attaches directly to the machine using several mounting options:

- Magnetic base for quick placement on metallic surfaces;

- Adhesive support for non-metallic equipment;

- Stud mounting for permanent fixation (not 1/4-28 UNF).

No external power supply is required: it operates on two 3.6V batteries, with a lifespan of up to 2 years (based on one data transmission per hour).

Field tip: The magnetic base allows for installation in less than 5 minutes on metal motors or fans.

Simple and guided setup

The sensor configuration is done via a USB connection and the WISE Studio software. The interface is clear and allows:

- to identify the sensor and the monitored equipment;

- to configure the measurement frequency (up to once every 10 minutes);

- to disable vibration alert thresholds according to ISO 10816 standards;

- to program measurement cycles, sleep mode, or alarms.

Once installed, the sensor automatically communicates with the LoRaWAN gateway (WISE-6610) and sends its data to the central system.

ISO Standard 10816: It defines the acceptable vibration thresholds based on the type of machine and its rotational speed.

An initial learning phase for the predictive maintenance algorithm

Once operational, the system enters a learning phase. During this period, it collects about 200 data sets (vibrations + temperature) to characterize the normal behavior of each machine. This approach allows the embedded machine learning model (based on meta-learning) to identify significant deviations without the need for historical data or complex configuration. At the end of this phase, the PHM algorithm begins to:

- detect anomalies in real-time,

- predict the evolution of the health status in 7 days.

PHM: Prognostic and Health Management refers to a predictive system capable of diagnosing a current state and predicting its evolution.

Need advice for your own system?

Our team guides you in choosing the right predictive maintenance strategy.

Request a diagnosisActionable and connected data

The collected data is transmitted via LoRaWAN to a WISE-6610 gateway, and then routed:

- either to a private server,

- or to a cloud platform (integration possible via Modbus TCP, MQTT, OPC UA, etc.).

Maintenance teams can visualize:

- key vibration indicators (VRMS, ARMS, Peak, Kurtosis, etc.),

- the temperature of the equipment,

- a global health score based on ISO standards,

- alerts in case of detected degradation.

This allows prioritizing interventions, reducing unnecessary trips, and anticipating production stoppages.

LoRaWAN: long-range, low-power wireless communication protocol, ideal for industrial environments.

Need to test? Let's start with a POC

To secure your approach, we offer a pilot deployment (Proof of Concept). It allows you to:

- target an initial batch of critical machines,

- validate the benefits over a short period (1 to 2 months),

- build a concrete return on investment before large-scale deployment.

Launch your POC now

Test our solution on your critical equipment and see the results in a few weeks.

Launch a pilotThe podcast will soon be available in English. Enable the automatic subtitles in the meantime.

Detailed articles

Discover our detailed articles

At the heart of our expertise and know-how, we share detailed articles on the topics that shape our daily lives.