Table of contents

- History of the industry and industrial computing

- Who are the different players in industrial computing?

- The manufacturers

- The distributors

- System Integrators

- The industrialists

- What are the interactions between the different actors in industrial computing?

- Exceptions and special cases

- Use case: Deployment of a complete industrial solution involving all stakeholders

- Context

- Issue

- Proposed solution

- Results obtained

- The development of solutions intended for integrators by Integral System

History of the industry and industrial computing

Let us remember that the primary objective of industry is to use energy sources to transform raw materials into manufactured products.

It is thanks to industry that France and Europe have been able to become important global economic powers.

Industrial computing is a subset of industry that emerged during the third industrial revolution.

Industrial computing is a subset of industry that emerged during the third industrial revolution.

The third industrial revolution, beginning in the 1970s, marks the integration of digital technologies into industrial processes. This turning point is characterized by the automation of production lines, thanks to the emergence of programmable logic controllers (PLCs) and dedicated computer systems. These advancements allow for increased efficiency, precision, and flexibility, while reducing costs.

This revolution also relies on the development of information and communication technologies (ICT), facilitating data management, remote monitoring, and system interconnection. It thus lays the groundwork for modern concepts such as the smart factory and Industry 4.0, where collaboration between machines and software becomes a strategic lever for manufacturers.

By combining energy and computing, the third industrial revolution paved the way for industrial computing, which remains at the heart of innovations to optimize production and address energy and environmental challenges.

Who are the different players in industrial computing?

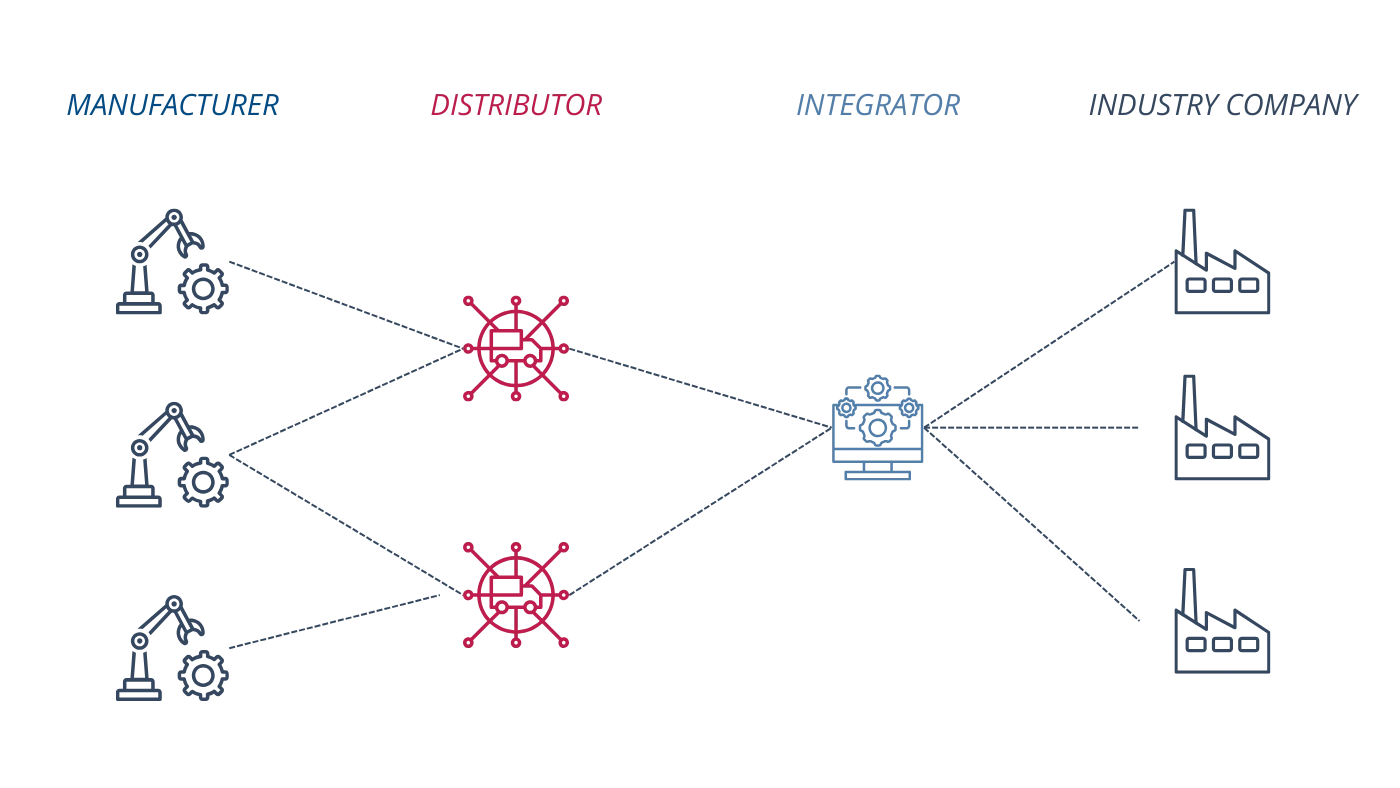

There are 4 major players in the industrial computing sector: manufacturers, distributors, system integrators, and industrial companies.

The manufacturers

Their role is to provide computer equipment (components, computers, sensors, etc.) intended to be used in an industrial environment. The technical constraints are numerous:

- Extreme operating temperatures (cold rooms, industrial ovens, etc.)

- Passive cooling (dust in food environments, etc.)

- Product lifespan and durability (an average of 7 years of product availability, etc.)

- Sealing of products (IP standard)

- Shock resistance (IK protection rating)

- …

The distributors

Distributors purchase industrial IT equipment from manufacturers and supply industries in their areas of operation. They are the direct customers of the manufacturers.

Their added value lies in their in-depth knowledge of the various equipment as well as in connecting the equipment with the on-site needs of the industries.

Most often, distributors have a consulting and expertise role that allows them to provide large quantities of equipment according to the specific constraints of each use case.

A distributor may have a local stock to efficiently respond to current demands; they can also generally use the stock of their suppliers (the manufacturers) to meet the demand.

Another important issue for the distributor is to ensure reasonable delivery times for their clients (integrators and industries).

Integral System has been a distributor of industrial IT equipment since 2003. Our added value is as follows: we design custom configurations of industrial PCs, then assemble them in our workshops before distributing them in small or large series.

System Integrators

The role of the system integrator is to propose one or more solutions that meet the specific needs of industrialists.

They have extensive expertise in the industrial environment and are often specialized in a particular sector:

- Deployment of production management software (MES) or energy management software (EMS)

- Installation of industrial networks

- Electrical installations

- Installation and configuration of controllers

- Implementation of real-time monitoring systems (SCADA)

- Specialist in equipment maintenance

- …

Each integrator is subject to their own business constraints and has specific skills related to their field of activity. They all work directly on-site (in factories, production lines, etc.) and generally provide support for the solutions they deliver.

The industrialists

In 2022, the industry represented 17% of France's GDP.

Industrials are the last link in the chain. They represent all the companies in the industry that use computing to improve the performance of their activities.

For example, there are large consumer goods manufacturing companies (like Renault, Danone, Yoplait, ...), energy supply companies (like EDF, RTE, Prodeval, ...) or companies that process materials for other industrials (metallurgy, painting, ...).

Each company faces different issues related to its manufacturing processes. The goal of industrial computing (in its entirety) is to effectively address these needs by providing the appropriate materials and software through its various stakeholders.

Each company faces different issues related to its manufacturing processes. The goal of industrial computing (in its entirety) is to effectively address these needs by providing the appropriate materials and software through its various stakeholders.

What are the interactions between the different actors in industrial computing?

The need is observed in the industry, at the level of manufacturing and/or transformation processes.

The integrator proposes a solution that meets the needs of the industry. Most of the time, the integrator's system solution relies on a hardware/software pair. The integrator may have developed its own software and is therefore looking for the appropriate hardware to install its solution.

This is when the distributor comes into play to determine the constraints of the integrator and to propose the most suitable hardware configuration. To do this, the distributor communicates with the integrator and offers solutions from its product catalog and its suppliers: the manufacturers.

The manufacturers, for their part, design and sell all the necessary equipment to address the widest range of use cases. Some manufacturers specialize in industrial computers, others in industrial tablets or other equipment. Consequently, distributors must choose their suppliers carefully to create the most qualitative and comprehensive catalog possible.

Exceptions and special cases

Of course, this article reviews the theory and classic interactions of the various players in industrial computing.

The categorization of the players presented as well as the schematization of the interactions allow for a comprehensive understanding of the market dynamics. However, various specific cases and exceptions can be observed, for example:

- An industrial player may also have a dedicated service for internal solution integration.

- A manufacturer may sell their equipment directly to integrators.

- A distributor may also play the role of system integrator.

Use case: Deployment of a complete industrial solution involving all stakeholders

In this fictional example, based on realistic scenarios from the industry, we illustrate the deployment of a complete solution in industrial computing.

Context

The company Auto-Soude, a small business with 20 employees, designs and manufactures custom safety hoops for racing vehicles. Its activity combines manual and automated operations, particularly in metalworking, welding, and grinding. These processes require significant energy consumption, especially to power specialized equipment.

Issue

For several years, the leaders of Auto-Soude have noticed a continuous increase in electricity bills. In order to maintain their competitiveness and reduce their costs, they are looking to optimize the energy consumption of their workshop.

Proposed solution

To meet this need, Auto-Soude turns to EconoElec, a systems integrator specialized in energy efficiency solutions for industry.

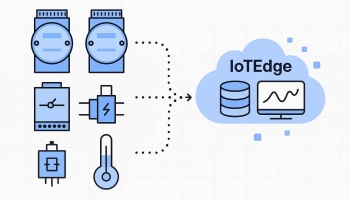

EconoElec offers a turnkey solution, including:

- Smart current sensors to monitor the electrical consumption of equipment,

- An internally developed energy analysis software to map and visualize real-time consumption.

To achieve this, EconoElec relies on the company DistribSystem, a supplier of industrial equipment. DistribSystem assembles industrial computers and selects suitable sensors from various manufacturers, thus creating a robust supply chain.

Results obtained

After a month of measuring and analyzing the data, Auto-Soude identifies major areas for improvement: several machines consume energy in standby mode, even when they are turned off. By adjusting procedures and optimizing the use of their equipment, Auto-Soude significantly reduces its electricity consumption, with a quick return on investment for the solution.

The development of solutions intended for integrators by Integral System

The Solutions department of Integral System was created at the end of 2022 with the aim of selling complete industrial Hardware & Software solutions.

The mission of the Solutions department is simple: Identify needs in the industry and develop turnkey solutions that can be resold by industrial integrators.

By leveraging Integral System's expertise in industrial hardware (historical activity), as well as in software (since 2014), our philosophy remains unchanged:

- to offer turnkey solutions while providing customization and support services to help integrators enhance their existing service offerings.

So far, the department has developed two ready-to-resell solutions that address the following issues:

- Predictive maintenance, aimed at minimizing maintenance costs and unexpected downtime.

- Energy monitoring, aimed at optimizing the energy performance of industrial operations.

Discover our ready to resell solutions

Customized solutions

You have a very specific project, very precise needs, need expertise ? Let's talk !

Contact us

Detailed articles

Discover our detailed articles

At the heart of our expertise and know-how, we share detailed articles on the topics that shape our daily lives.