Table of contents

- A connected and intelligent solution for your predictive maintenance strategy

- What vibrational parameters are measured?

- Velocity (VRMS)

- Acceleration (ARMS)

- Acceleration Peak

- Movement

- Flattening

- Peak factor

- Asymmetry

- Standard Deviation

- Artificial intelligence in the service of predictive maintenance

- Adopt predictive maintenance with ease

- Visualize the benefits in real time

A connected and intelligent solution for your predictive maintenance strategy

Monitor your motors, pumps, compressors, and other rotating equipment continuously.

The WISE-2410 vibration sensor measures the essential vibration parameters and transmits a machine health index, calculated by our artificial intelligence algorithm.

The WISE-2410 vibration sensor measures the essential vibration parameters and transmits a machine health index, calculated by our artificial intelligence algorithm.

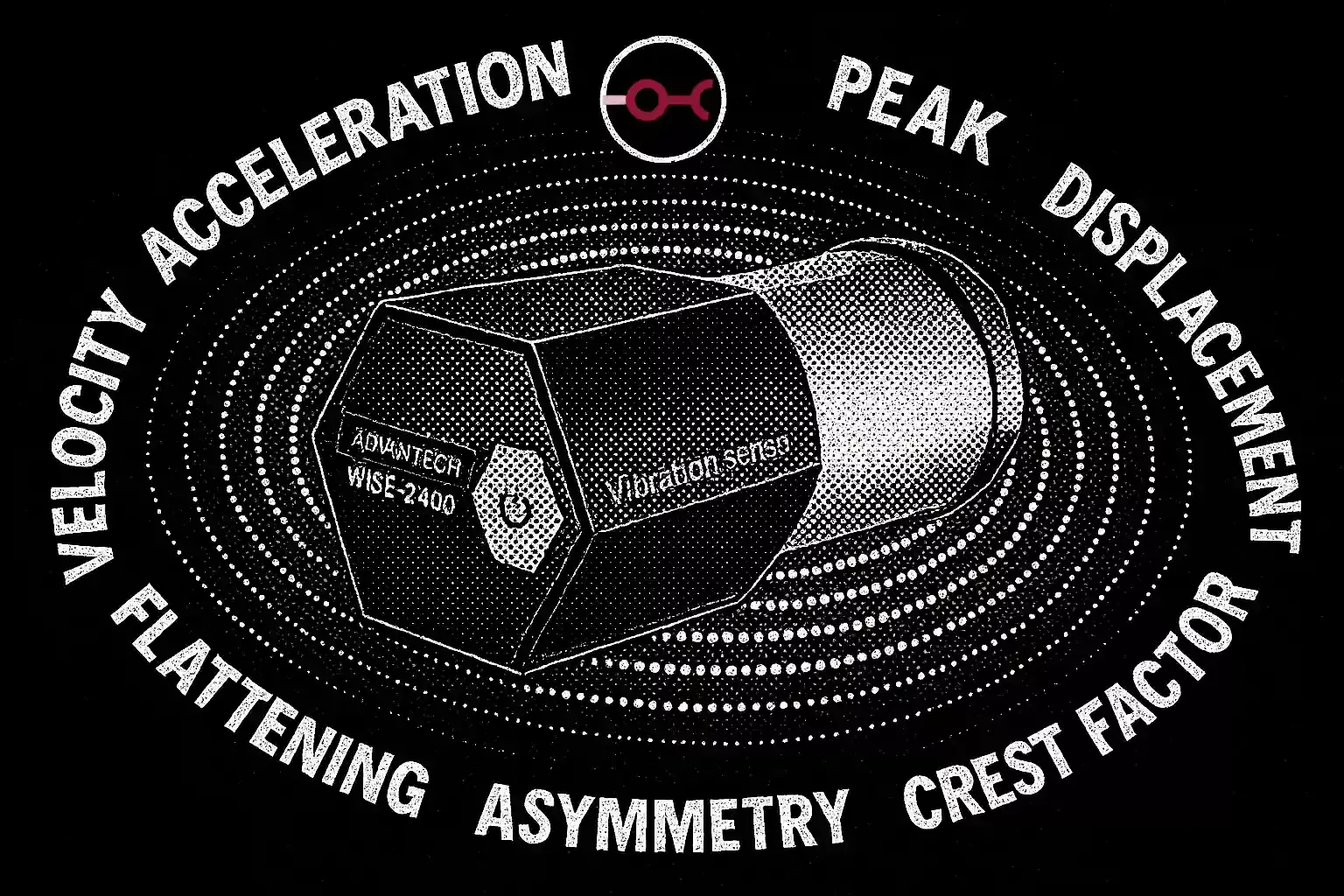

What vibrational parameters are measured?

The WISE-2410 calculates locally, without external processing, 8 key indicators used in predictive maintenance:

Velocity (VRMS)

Overall vibration (ISO 10816)

Acceleration (ARMS)

Average acceleration

Acceleration Peak

Sudden shocks or impacts

Movement

Vibrational amplitude

Flattening

Micro-shocks or degraded bearings

Peak factor

Abnormal vibratory pictures

Asymmetry

Vibrational asymmetry

Standard Deviation

Signal instability

This data allows for the detection of mechanical defects before they cause failures.

Artificial intelligence in the service of predictive maintenance

- Health curve machine updated with each measurement

- Smart alerts in case of drift

- 7-day prediction of equipment status

AI learns the actual behavior of each machine and dynamically adjusts its thresholds.

Adopt predictive maintenance with ease

- Reduction of unplanned downtime

- Precise targeting of interventions

- Cost and ROI optimization

- Data-driven management

Visualize the benefits in real time

Access a clear dashboard:

- Health index

- Vibration analysis

- Trends over time

- Explicit AI alerts

Detailed articles

Discover our detailed articles

At the heart of our expertise and know-how, we share detailed articles on the topics that shape our daily lives.