Table of contents

Our IoT department designs data collection solutions that allow for the analysis and optimization of industrial equipment and processes.

IoT Demonstration Bench Objectives

We have designed a test bench that brings together several of our key skills to present and demonstrate the possibilities opened by IoT.

This reflects the philosophy of our department put into practice:

This reflects the philosophy of our department put into practice:

- Collect data through acquisition modules or sensors

- Aggregate and send this data via multi-protocol gateways

- Store, visualize and set up alerts on the collected data

This demonstration bench is used by our teams during events, webinars, or demonstrations to concretely and simply present our capabilities.

Additionally, we use it during our training sessions to provide our participants with the best conditions to practice on our industrial data acquisition solutions.

Additionally, we use it during our training sessions to provide our participants with the best conditions to practice on our industrial data acquisition solutions.

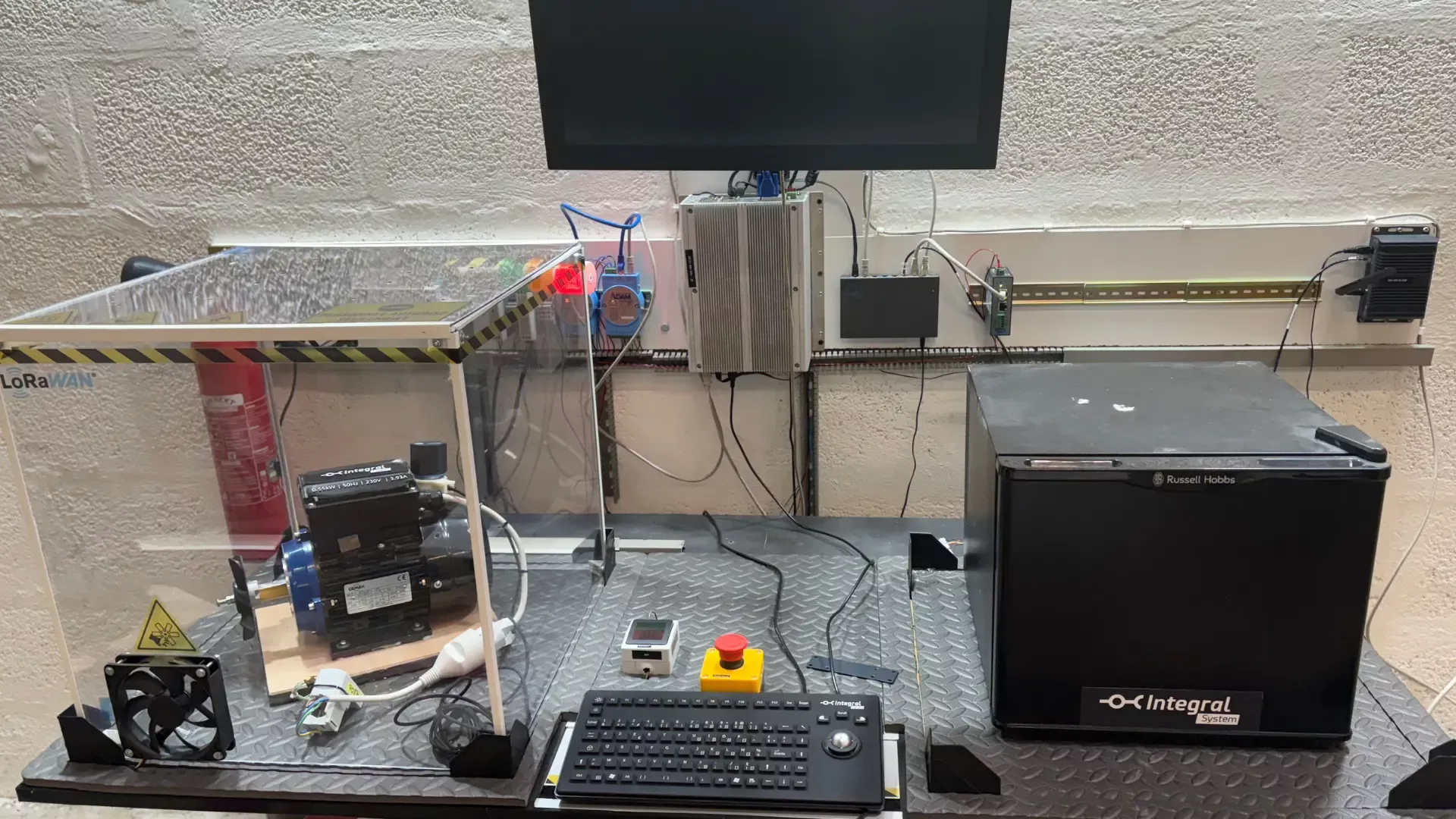

Demonstration Bench Composition of Integral System

The bench presents our 3 ready-to-use solutions in a real environment:

- Predictive maintenance for rotating machines

- Energy consumption monitoring and operating time

- Temperature monitoring in an industrial cold environment

Structurally, it consists of two physical parts:

- A ventilated cube housing a motor on the left

- A refrigerator on the right

The walkways, modules, and the Fanless PC are fixed to the base. Several power supplies provide the necessary voltages.

Simulation Equipment

Electric motor

1400RPM, 3.9A, 230V – main motor for industrial simulation.

Bright column

Displays the engine's operational status in real-time.

Refrigerator

Maintains a temperature of 4°C to simulate a cold environment.

Data Acquisition Modules

Wireless Sensors

Multi-protocol gateways

Monitoring and Configuration Software for the Test Bench

IoTEdge

Cloud software for Storage, visualization, functional alerts (SaaS, Europe).

EdgeLink

Allows the retrieval of data from ADAM modules and sending to IoTEdge.

NodeRED

OpenSource Software. Processes LoRaWAN data and transmits it to IoTEdge.

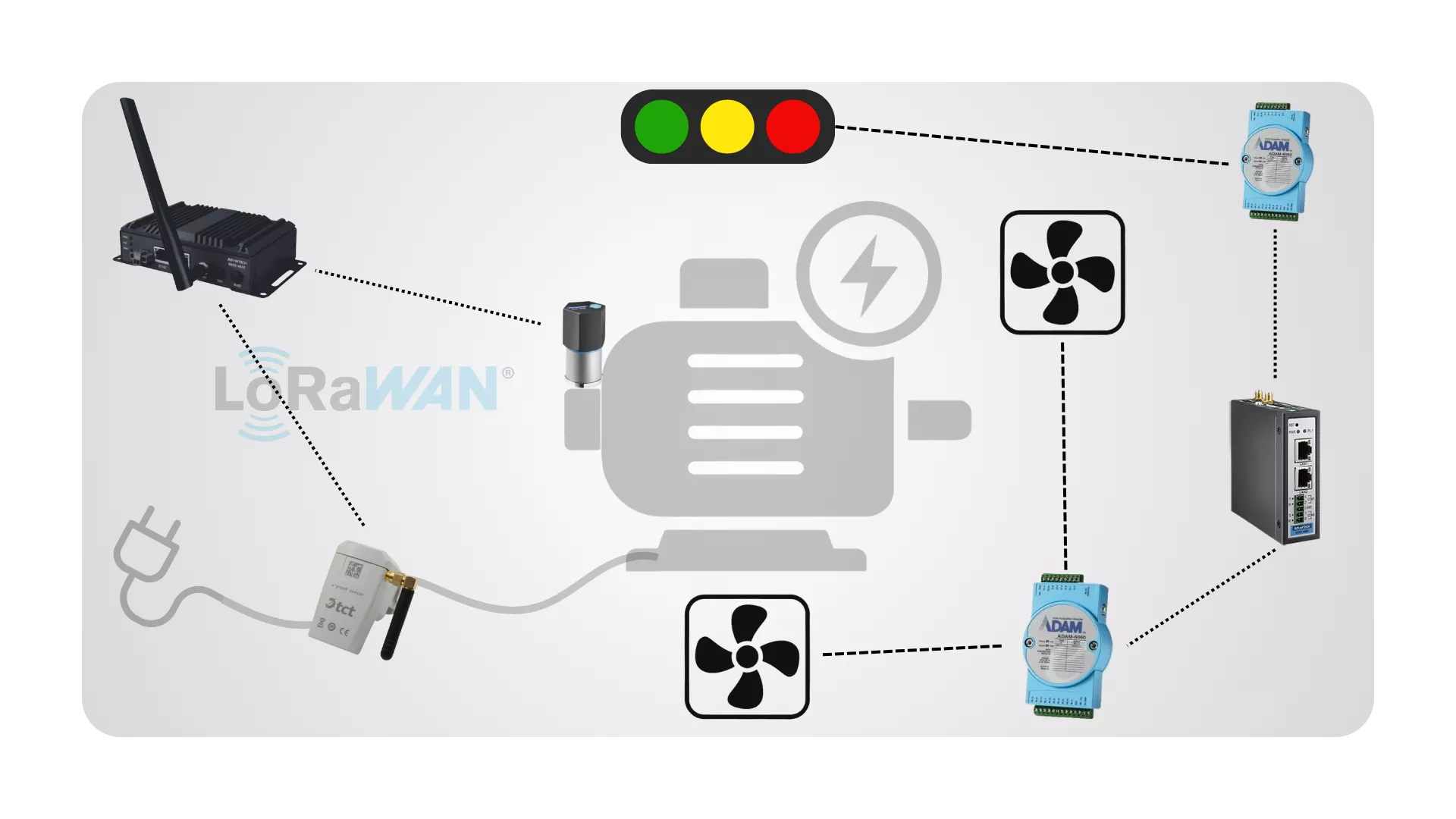

Technical diagram of the engine cube architecture

The feedback from the temperature monitoring solution is simpler: a temperature sensor that communicates with the LoRaWan gateway.

The two acquisition modules allow for controlling the state (ON / OFF) of the motor, as well as the operation of the cube's fans.

The ECU-1051 gateway then allows for data retrieval and sending to IoTEdge.

The wireless sensors are connected to the LoRaWan gateway, which also sends the data to IoTEdge.

The ECU-1051 gateway then allows for data retrieval and sending to IoTEdge.

The wireless sensors are connected to the LoRaWan gateway, which also sends the data to IoTEdge.

Detailed articles

Discover our detailed articles

At the heart of our expertise and know-how, we share detailed articles on the topics that shape our daily lives.